EV Infrastructure Products |

Lynx, Newport

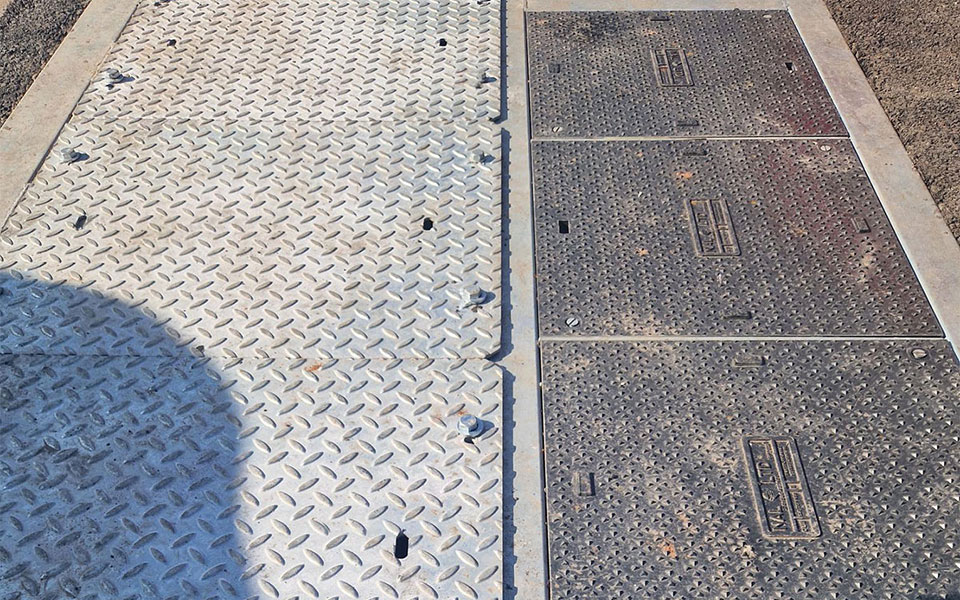

NAL EV infrastructure products have been adopted for several charging points within a supermarket car park in Lynx, Newport.

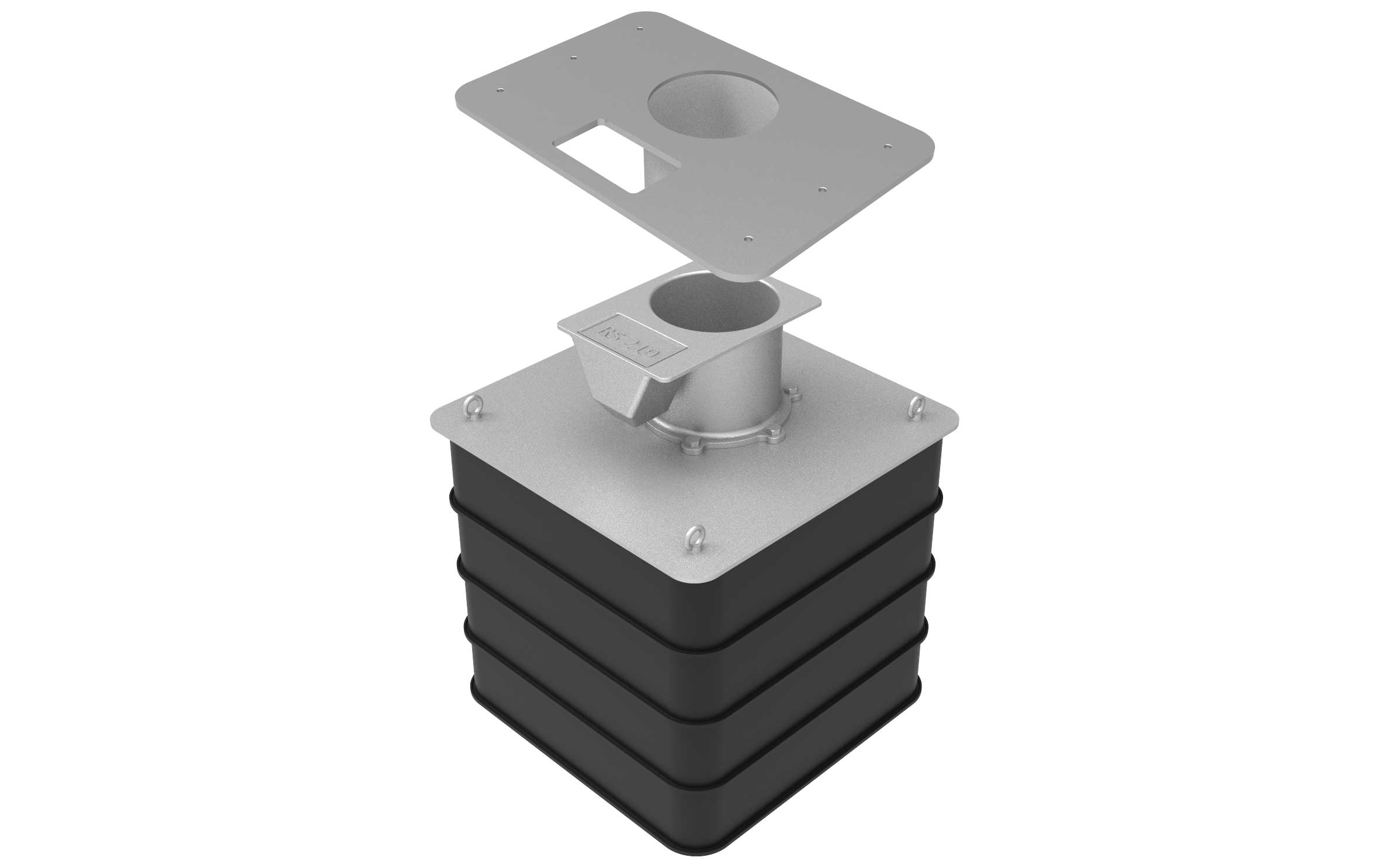

NAL High Power Charger (HPC) foundations were installed to accommodate EV dispenser units. This unique foundation provides the flexibility to house all manufactured and bespoke high power dispenser units.

Consisting of a NAL Retention Socket coupled with a STAKKAbox ™ Modula Access Chamber, this modular, universal foundation system affords unrivalled flexibility for accommodating the bend radius of large power cables required for these high powered dispensers.

As demonstrated in this case study, the civil works were completed before the arrival of dispensers. This fully ducted system also allows the electrical contractor to pull cables through the ducting to be stored safely within the Retention Socket, which is easily accessed via the socket’s aperture. While awaiting the arrival of the dispenser units, the Retention Socket aperture is sealed with a pedestrian plug, creating a safe walking space free of trip hazards.

Furthermore, the HPC foundation future-proofs the site, allowing the dispensers to be upgraded as the technology evolves without further civil installation.

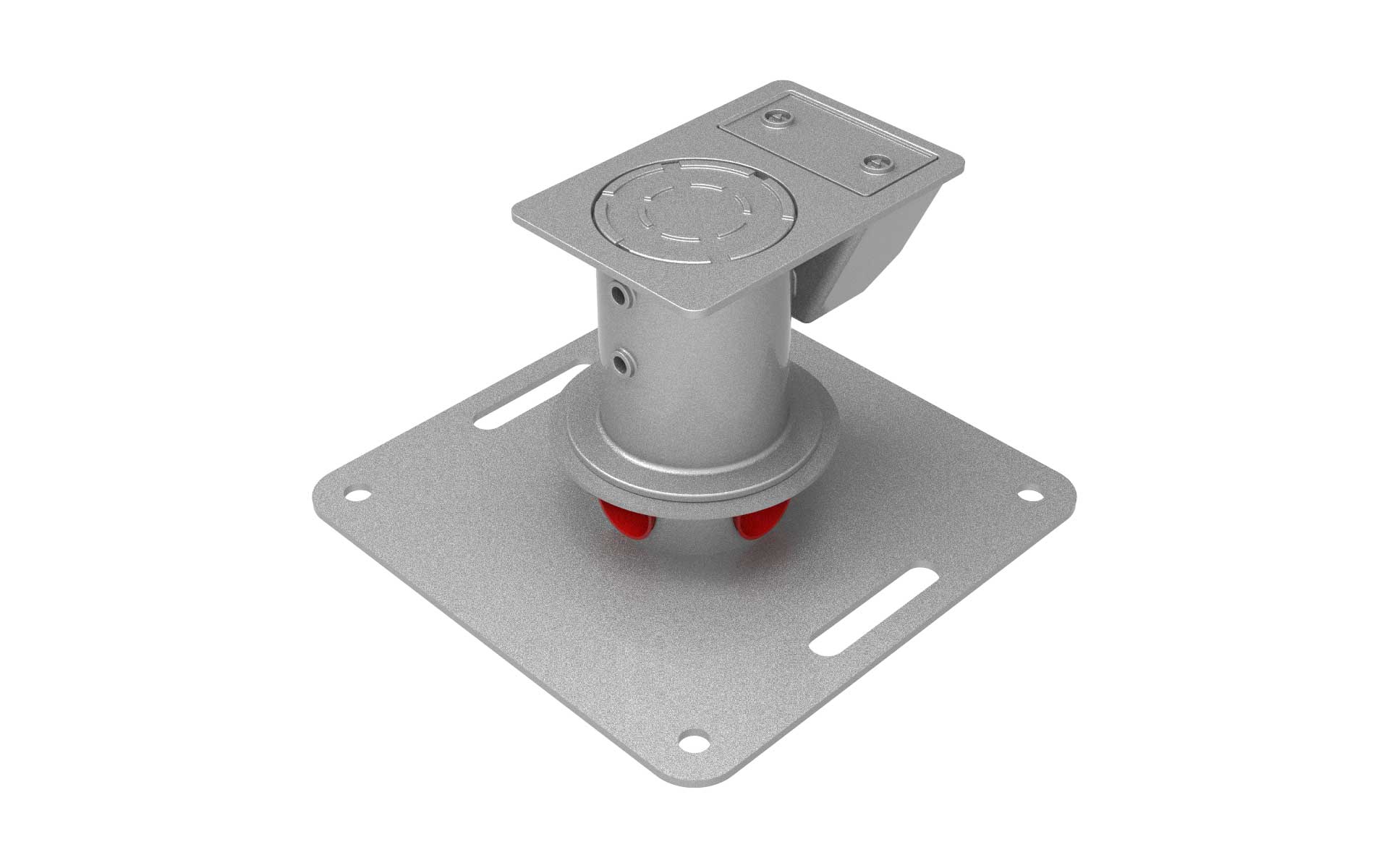

Retention Sockets have also been utilised to house the steel bollards protecting the dispenser units from vehicular impact. As these bollards are prone to impact damage, the Retention Socket system provides a reusable foundation, swiftly removing damaged bollards without the requirement for additional civil works, saving time, disruption and maintenance costs.

NAL EV Cabinet Base systems were installed to support the installation of the site’s power cabinets. This modular system provides a secure foundation for single and multiple cabinet configurations and is designed to suit individual site requirements.

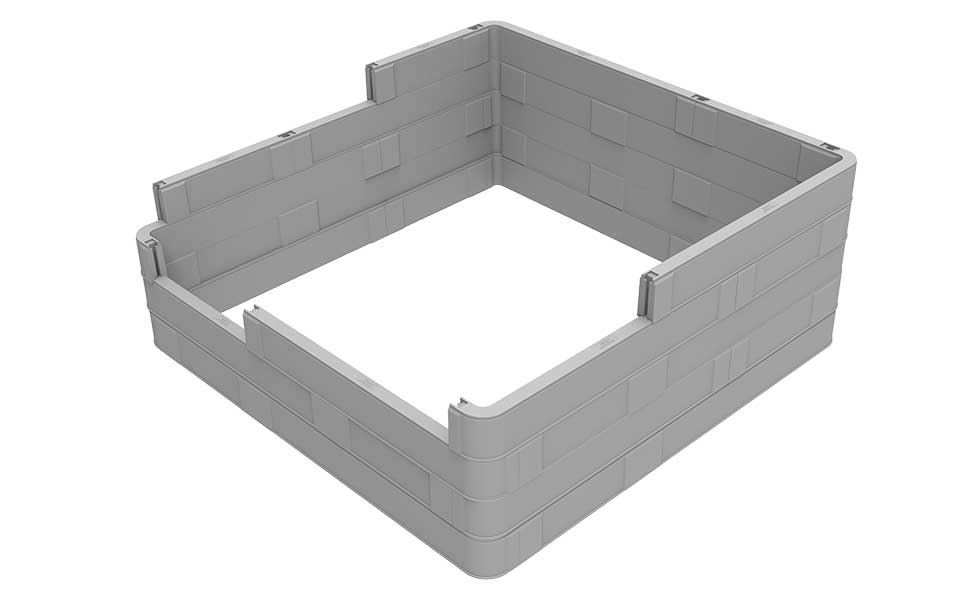

This Cabinet Base is significantly faster to install than traditional cabinet foundations, which require shuttering and reinforcement with rebar in preparation for a large-scale concrete pour, all of which need skilled labourers and incur a significantly high carbon footprint.

On the other hand, the NAL EV Cabinet Base consists of a STAKKAbox ™ ULTIMA Connect Access Chamber and galvanised steel Cabinet Modules, which are bolted and secured to the STAKKAbox. Each module provides one area for a cabinet to be mounted and a second area for a Composite Access Cover.

As demonstrated in this case study, the Cabinet Base was installed before the cabinets arrived on-site. Similarly to the HPC Foundation Pedestrian Plugs, this system utilises blanking plates covering the vacant module spaces, ensuring the site is safe for the general public.

Once the cabinets are ready for landing, the Cabinet Base provides a significantly large working area, granting engineers easy access to cables and extra space for larger cables typically associated with cabinets required for high power charging.

Furthermore, the system allows for easy cable interconnectivity between cabinets, simplifying the addition of future cabinets or upgrading and being positively ducted to the HPC Foundations.