Energising the Grid:

The Surge of High Power Charging Networks

It’s incredible to look back over the last four years at what Gridserve has achieved with their impressive rollout of High-Power Charging hubs.

In 2021, Gridserve had two active sites offering level 3 charging: the Braintree Electric Forecourt® and the Moto Rugby. By the end of 2022, this number had jumped to 11 sites, a 450% increase. By 2023, the numbers sprung again, this time to 40 sites. So, how was this achieved?

Key considerations

Gridserve understood the key considerations for an EV infrastructure rollout of this scale. While there are many important factors to consider, one critical factor is time. The more streamlined the installation process, the sooner the site will be live and open to the public.

Traditional foundations often require manufacture-specific foundation fixings, shuttering and rebar, which are lengthy and costly processes. Our HPC Foundations and Cabinet Bases provide a seamless system for establishing EV charging dispensers and feeder pillars.

Stackable access chambers

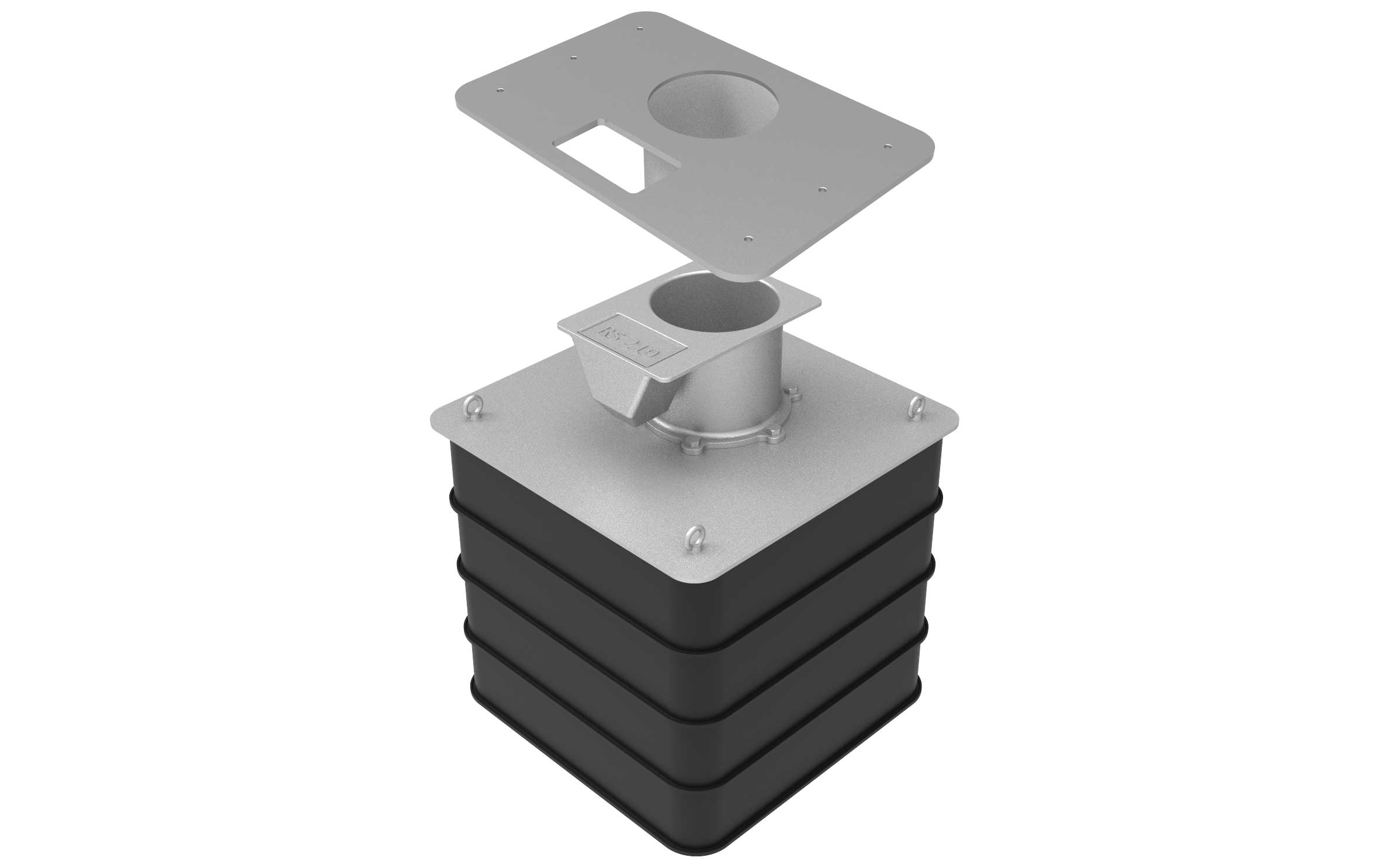

The stackable ring sections of the STAKKAbox ™ access chamber range ensure these systems are assembled quickly. They are also easily adapted for cable duct requirements on-site before being positively connected via the ducting network.

Additionally, both systems provide an improved working space with a greater cable-bending radius to pull HPC cables ahead of landing dispensers, LV pillars and power cabinets.

Design now to future proof for tomorrow

Looking forward, Gridserve understands that EV charging technology moves faster than this rollout. With this in mind, they recognised the importance of future-proofing their sites.

Our HPC foundations utilise an adapter plate system, a bespoke steel plate designed to mirror the footprint of any OEM dispenser. When more powerful dispensers become available the adapter plate is released from the Retention Socket head, and a replacement plate secured just as quickly. Furthermore, additional HPC foundations can be installed during the major groundworks, in anticipation of increased uptake in demand. Unused foundations are safely capped off with pedestrian plugs, ready to be utilitsed.

Additionally, the modular design of the Cabinet Base system also enables spare cabinet modules to be installed and sealed, ready to accept additional feeder pillars to support the increased demand. This is also the achievable for future bollard and signage with the use of the Retention socket.

Frontline protection

CPOs understand better than most the value of on-site equipment and the importance of protective measures to mitigate the risk of vehicular damage.

Most charge stations feature bollards positioned at a suitable distance from the dispenser to prevent such accidents. However, accidents do happen, and bollards will get damaged. It’s safe to assume CPOs would prefer a bill for a new bollard than a new dispenser. Still, suppose that the bollard was directly buried in the ground. In that case, maintenance costs quickly increase to pay for temporary barriers for public safety, additional civil works, labour, material, and of course, time.

Gridserve recognised this foresight and installed its bollards and signage posts in NAL Retention Sockets. If a bollard or post becomes damaged, it’s removed from the socket and replaced, and Gridserve only pays for the new bollard, providing significant savings in maintenance costs.

Utilising NAL EVi solutions and their respective benefits has significantly contributed to establishing each Gridserve site, helping to transform EV uptake in the UK.