Solving today’s challenges with tomorrow’s solutions

EV infrastructure considerations

There are few more prominent examples of the impact of decarbonisation than the move to reduce the number of internal combustion engine vehicles on our roads.

The importance of cutting carbon emissions has been underlined in a European Environment Agency report, which found that lifetime greenhouse gas emissions (GHG) of electric vehicles were 17-30% lower than those of petrol and diesel cars. This difference is expected to increase as EVs and renewable energy production become cleaner and more efficient.

Establishing infrastructure

A critical aspect is the growing network of Electric Vehicle charging points required to keep the nation’s increasing fleet of EV vehicles running. The importance of getting this infrastructure installed in the ground can be seen from the amount of public and private funding to build more accessible electric vehicle charging stations and hubs, not just for public day-to-day vehicle use but also for the expanding commercial fleets of electric trucks and buses which support the UK’s vast haulage and public transport sectors. However, an added layer of complexity is that the construction of this infrastructure must itself have sustainability at its core to align with net zero goals and reduce carbon impact.

Innovating for sustainable construction

To better understand sustainable construction in this space, policies and regulations such as the UK’s Climate Change Act, the ‘building to net zero’ scheme, and The Paris Agreement of 2015 have outlined green building principles to guide the industry’s collective efforts. This prioritises factors such as durability, energy efficiency and waste reduction, embedding sustainability into design to re-invent the way our world is built.

At NAL, this has driven us to consider how EV charging infrastructure can be designed, installed, maintained, and upgraded - to ensure that they can meet contemporary and future demands regarding capability and environmental impact reduction. When considering this, it’s important to note that much of an EV charger (or dispenser as it’s known in the industry) is underground and unseen by the casual observer. Traditionally, this would mean a lot of excavation and concrete to install the plug-in chargers, whether on forecourts, car parks, roadsides, or at destinations. In contrast to the traditional approach, the modular nature of NAL EV solutions provides a sustainable alternative that significantly reduces the amount of concrete needed during installation. This makes it a more efficient approach, as it minimises the time, resources, deliveries and labour required while speeding up and standardising the installation process.

Modern methods in action

At NAL, the combination of our Universal EV Foundations and EV Cabinet Base systems makes it quick and easy to create an EV charging station or hub suitable for any type of LV system or dispenser unit—fast, rapid, or high-powered, regardless of where the units are manufactured. This is an agnostic universal infrastructure solution.

EV Cabinet Base

Following excavation, the Cabinet Base, built from a lightweight GRP chamber, is assembled by hand and a mallet without heavy machinery or specialist equipment. A robust chamber is built up section by section in a Lego-like, overlapping fashion. It is rapidly constructed and then easily drilled for suitable duct entry point requirements. This process means that labour-intensive shuttering, rebar reinforcement, and concrete pours, typically required for an EV charging station, can be eliminated, reducing embedded carbon and speeding up installation time.

The cabinet frames, with precision-engineered mechanical fixing points that positively accept the LV panels, are then secured to the chamber via through bolts, creating a robust and stable structure. Access covers are then installed, the area around the chamber is backfilled with compactable material, and the surrounding surface is covered. All in all, this process can be done in hours, not the days or weeks it would take to wait for concrete to be delivered, poured, and cured, especially if there are adverse weather and ground conditions.

For most projects, this can significantly reduce the installation time by up to 80% while reducing labour costs, deliveries, waste, and the need for carbon-intensive equipment like an industrial mixing lorry. All the NAL materials are delivered on pallets and can be stored onsite, streamlining the process and making it more efficient and cost-effective.

This system's adaptability means charging stations and hubs can be arranged in a wide array of configurations to suit different locations, manufacturer requirements, and cabinet applications, including power and rectifier cabinets, communications cabinets, low-voltage pillars, and switchgear cabinets.

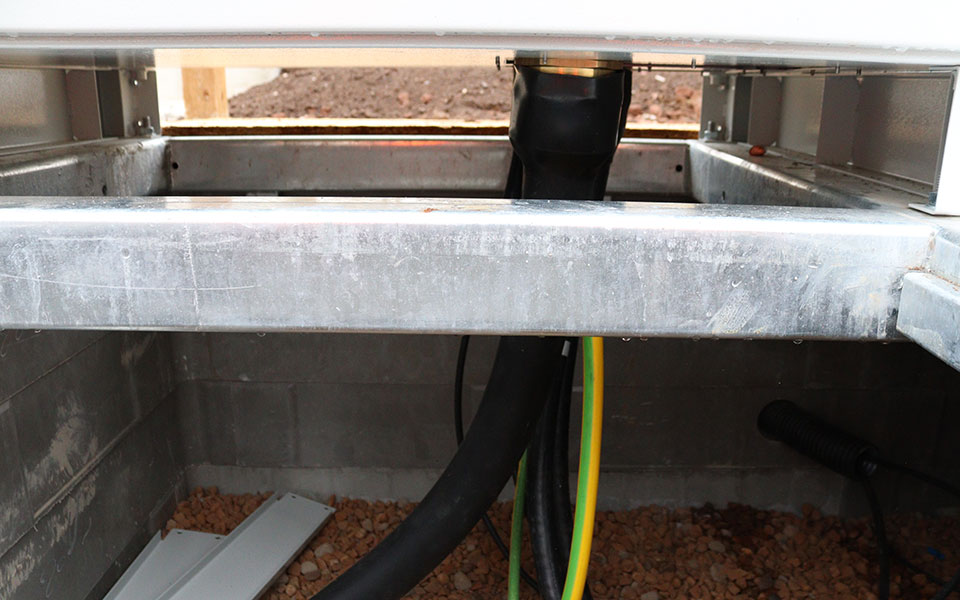

The space inside the Cabinet Base System and the locking access covers allow for multiple cable routes and ducting installations that can be easily accessed. This makes cable interconnectivity quick and efficient during initial installation and accommodates future extensions, upgrades, and maintenance.

Case study: Gateway Cafe, Cirencester

This flexible, modular design makes the EV Cabinet Base system ideal for EV parking infrastructure developments, such as the EV charging bays at a cafe in Cirencester, Gloucestershire, UK. The system incorporated bases for the site’s power cabinet and a single LV feeder pillar, with provisions to accept a second feeder pillar in the future, should more chargers be required. In addition to the futureproof aspects, the simplicity and speed of the system meant an overall faster build programme, ensuring the business could sooner meet its customer's needs for EV charging points.

Growing with demand

As we’ve outlined, the EV landscape is constantly growing and evolving. This means charging points that can’t adapt or improve will likely become obsolete quickly. Indeed, this is still a very new area of technology and will change a lot in the coming years, with the average lifecycle of a charger potentially as short as 5-7 years.

Universal EV Foundation

The versatility of NAL’s Universal Foundation system allows for any charger hardware to be installed, from fast, rapid and high-power charger (HPC) dispenser units. The system utilises NAL’s universal foundation offering, the Retention Socket, or ‘NAL Socket’ as it’s known in the industry. The socket is a unique, reusable foundation used for installing electrical hardware and associated street furniture. This intelligent infrastructure solution allows assets to be removed, upgraded or serviced at any time, cutting out the need for future civil works.

When combined with the modular nature of the EV Cabinet Base system enables any charging station is easily scaled up to increase the number of charging points and their capabilities. Combined with the EV Cabinet Base system's modular nature.

NAL sockets can be quickly capped off during the initial installation phase with a supplied pedestrian cap, providing added aesthetic and safety benefits whilst allowing future hardware installations without the need for costly, further labour-intensive work. Sites can pre-install and establish more dispenser foundations that are safely sealed so that additional dispensers can be conveniently added l when demand or electrical capacity has reached the necessary point.

Traditional foundations wouldn’t allow this, as the dispenser must be installed to seal the system. Without it, the cable access point is left open, exposing the underground cable ducting. Left unattended, a traditional concrete base foundation can be hazardous, lead to cable theft, and impact the aesthetic of a professional charging hub location.

What’s more, NAL’s Universal Foundation system does not commit a charging station to a particular CPO (charge point operator). As previously mentioned, EV charging technology changes quickly. Like a domino effect, OEMs (original equipment manufacturers) need to be reactive to the demands of the industry, resulting in customers such as supermarket chains keeping their EV infrastructure up-to-date with the latest dispensing hardware. Like any industry, contracts end, allowing a different CPO to take over a facility's charging station. If the traditional installation method was used, more time-consuming and costly civil works would be required. This is where NAL’s universal foundation system stands apart, allowing the existing dispenser hardware to be easily swapped out for the latest model and new technology. This makes it simple to implement vertical upgrades and horizontal expansion.

Futureproofing EV networks

Electric Vehicle charging sites and hubs are being designed to accommodate the rapid advancements and growing demands of the electric vehicle industry and the uptake of EV and Hybrid vehicles. These sites include charging stations and infrastructure such as LV Panels, Power Cabinets and impact prevention assets, all engineered with adaptability and scalability to meet future technological, environmental, and user needs.

Key considerations for scalable EV infrastructure networks

Components can be easily upgraded or expanded without major civil installation work, allowing for the integration of new technologies and increased capacity.

Multi-level charging infrastructure, including high-power and ultra-fast charging capabilities, will significantly reduce charging times and cater to the next generation of high-capacity batteries.

Modular, sustainable products can reduce cost and carbon impact and speed up programme times with designs that minimise environmental impact and promote sustainability whilst futureproofing for future expansion and technology advancements.

Conclusion

Future-proofing EV sites is essential for supporting the continued growth of the electric vehicle charging infrastructure here in the UK. By focusing on scalability, multi-level charging, and environmental sustainability, the NAL Infrastructure products support the construction and development of these sites. The NAL EV Infrastructure products ensure that CPOs, OEMs, and installers of EV infrastructure installations are ready for future demands.

Collaboration is critical to sustainable infrastructure projects, so if you’d like to learn more about the NAL EV Infrastructure products and how they can futureproof charging destinations while minimising the site’s carbon footprint and speeding up installation time, contact a member of NAL’s expert team today.

Ends