Decarbonising transport:

the hidden roadside carbon hotspots

When people talk about decarbonising transport, the focus tends to fall on vehicle emissions. But the roads themselves, and everything we install on them, carry hidden carbon costs over decades.

The “Measuring Road Infrastructure Carbon” report from DecarboN8 quantifies how every stage (materials, transport, construction, operation, maintenance) adds up. We’ve zeroed in on two under-emphasised levers:

- Maintenance emissions (especially repair, resurfacing, replacements)

- Manufacturing / replacement frequency of street furniture

With that in mind, here’s a closer look at how X-Last bollards can reduce these carbon hotspots in real-world road projects.

EV Solutions

Material production

Material transport

Construction

Maintenance over 30 yrs

Maintenance is a smaller slice compared to materials, but it’s still an important factor. And crucially, replacements and repairs of ancillary infrastructure (signs, posts, furniture) fall inside or alongside that maintenance bucket.

Plus, repeated replacements amplify embodied carbon. Every time you manufacture and install a replacement, you incur materials → transport → construction emissions all over again.

If, then, you can reduce the frequency or scale of replacement operations, you can help decarbonise transport. You’re cutting both the “maintenance” and “manufacture / transport / installation” emissions associated with those carbon-intensive loops.

Where street furniture & retention matters

Bollards are often installed via permanently cast-in foundations or direct embedding. If one component gets damaged, you then need to dig, break out, install new civils, re-pour, and reinstall. This cycle is as disruptive as it is carbon-intensive.

Using X-Last bollards changes this.

- No need to demolish or rework civils every time. The bollard remains fully-functional

- No downtime, traffic disruption, and ancillary repair works (reopening trench, concrete works, reinstatement).

- No embodied emissions. The repeated “base + foundation” component is reused rather than remanufactured every time.

Utilising X-Last bollards means zero replacements over time. That reduction only compounds savings in manufacture, transport and installation carbon.

Put simply, each avoided replacement avoids an upset loop in the carbon lifecycle.

Quantifying potential carbon savings

While the DecarboN8 report doesn’t break out street furniture replacement loops explicitly, its framework lets us conceptually map where those loops fall. Mainly, within the maintenance and construction phases.

Suppose a steel bollard has a 30-year life-span. Due to damage or vandalism, however, it is replaced every 5–10 years. Each replacement then incurs:

- New material production (steel, aluminium, electronics, coatings)

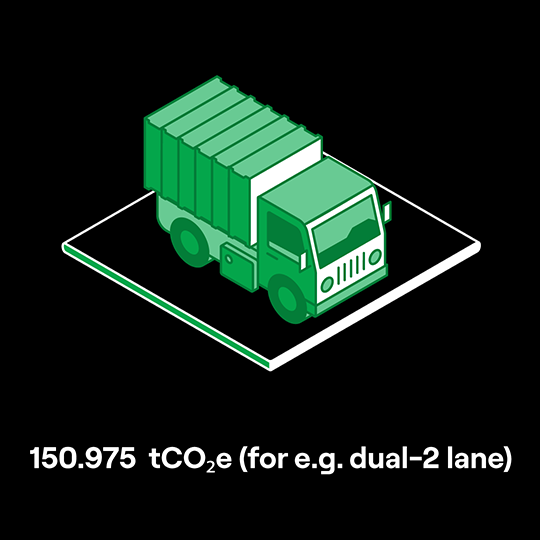

- Transport from factory to site

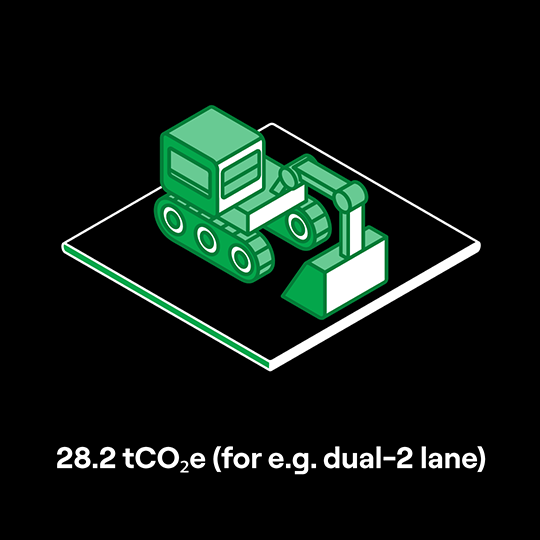

- Installation (equipment, labour, reinstatement)

- Partial civil works

If our X-Last bollard reduces replacement cycles from 4 to 1 over 30 years, we’ve cut three “mini-construction cycles.” Each of those typically touches all the carbon categories above.

If each replacement “mini-cycle” is 10–20% of the full installation emissions of that piece of furniture, the saving compounds. In aggregate across a network, that saving is meaningful.

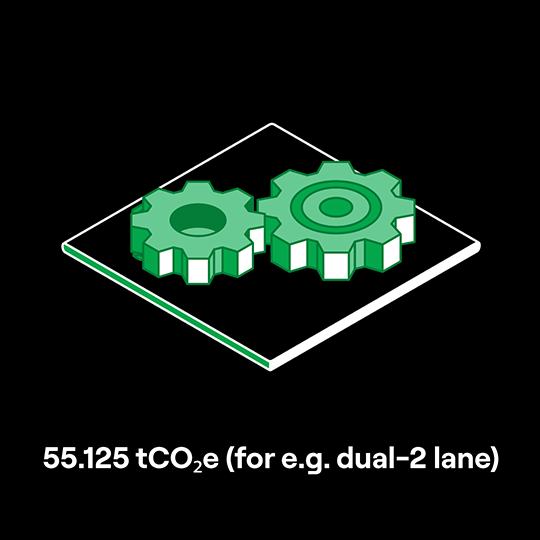

And, because maintenance is already ~55.125 tCO₂e over 30 years in the road itself, any reductions in bollard replacements will knock a portion of that off. All while reducing marginal load on construction and transport emissions.

Looking at the sensitivity analysis, using secondary / recycled materials or low-carbon alternatives (e.g. warm-mix asphalt, reclaimed aggregates) can reduce whole-life emissions by 2–12%. But those gains are undermined if repeated replacement cycles push you back into high-emission manufacturing loops.

So: retention + durability = extended leverage of low-carbon base designs.

How NAL’s approach helps deliver lower-carbon highways

NAL is decarbonising transport with roadside carbon reductions via the following core principles:

1. Removing the need for repeat groundworks during maintenance

Installing maintenance-free X-Last bollards means you never need to re-excavate civils to replace the bollard.

2. Extending street furniture asset life

X-Last bollards do not require replacement upon impact. In turn, this cuts the embodied carbon of repeated manufacture.

3. Minimising disruption and installation time

By cutting out replacement/maintenance process reduces congestion and vehicular carbon emissions, with less cars waiting in traffic during maintenance.

By combining these factors, NAL can help local authorities and highway operators reduce the embodied + operational carbon of their roadside infrastructure. (Far beyond what is possible from pavement-only measures.)

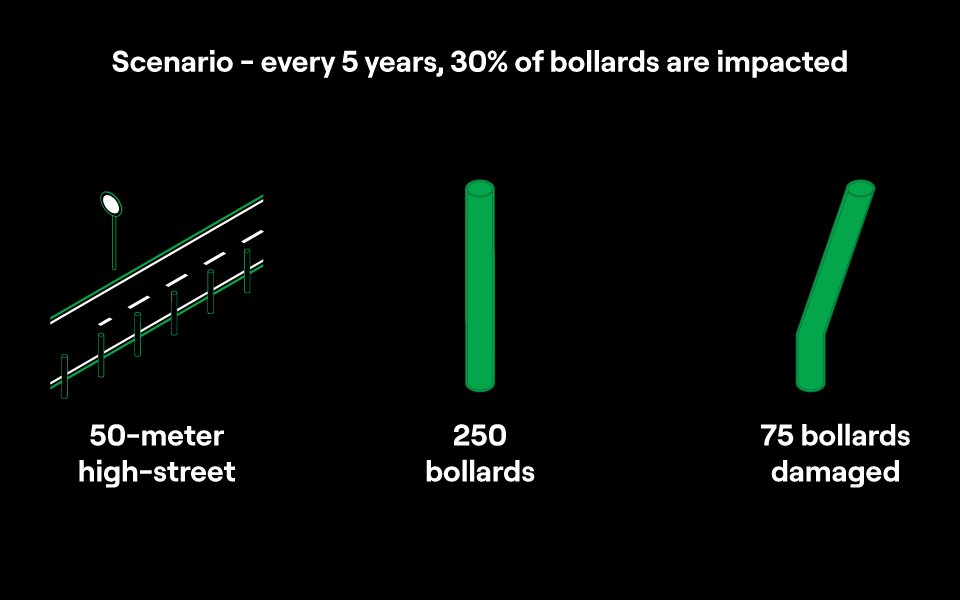

Scenario

Let’s imagine a local authority has:

- 500m high street

- 250 bollards

Under a conventional approach, every 5 years, 30% of those bollards require full replacement due to vehicular impact or vandalism (foundation + bollard). Over 30 years, that might be 4 full cycles.

With X-Last bollards, zero bollards will require replacement over a 30 year period

If each full replacement cycle of one steel bollard incurs, say:

- 1 tCO₂e (material + transport + works)

- For 75 bollards, that’s 75 tCO₂e × 3 avoided cycles = 225 tCO₂e saved

- Compared to the ~55.125 tCO₂e “maintenance” budget of the pavement itself, that’s a material offset

While this is a simplified and hypothetical example, it shows how cumulative small savings compound across assets.

Challenges & caveats

Shifting design emphasis from “least-cost today” to “lifecycle carbon cost” is increasingly essential. The industry faces a few challenges in that regard:

Baseline data gaps

Many authorities don’t yet track carbon impact of street furniture replacements in detail, so you must make assumptions or collect new data.

Upfront cost vs life-cycle benefit

X-Last bollards may cost more upfront; the carbon (and financial) payback must be proven over time.

System boundaries & attribution

Some emission savings may reside in “outside” scopes (supply chain, grid decarbonisation) or be counterbalanced by other works.

Despite these caveats, reducing lifecycle carbon cost remains an achievable goal – and one we’re committed to here at NAL.

The road to decarbonising transport

Roads and roadside infrastructure are long-lived, and their carbon footprint accumulates over decades. By focusing on reducing replacement cycles, eliminating redundant civils work, and designing for durability, we can chip away at often-overlooked carbon hotspots.

At NAL, we specialise in doing precisely that. Whether you’re segregating pedestrian walkways, implementing cycle schemes, or refurbishing, we can help you integrate X-Last bollards and low-carbon material thinking from day one.

To compare “business as usual” vs X-Last bollards enabled design in your next project, get in touch.