Infrastructure problem playbook

Reducing risk of injury via HIC value & passive safety in urban environments

Reducing risk of injury via HIC value & passive safety in urban environments

The problem

It’s an unfortunate – but not uncommon – reality that road users collide with street furniture such as bollards. In the case of pedestrians and cyclists, they’re likely to sustain serious and even irreversible injury.

So, this risk makes ensuring safety a priority for any urban planner.

The problem

A key metric in assessing the safety rating of street furniture:

The Head Injury Criterion (HIC)

Evaluating the potential severity of head injuries resulting from impacts.

During any impacts, traditional bollards – made from materials like steel – can pose significant risks:

High HIC values

Impacts with rigid bollards can result in HIC values as high as 3,500 — meaning a high probability of severe or irreversible injuries.

Lack of energy absorption

Rigid materials don’t absorb impact energy effectively – transferring the full force to the individual.

Structural damage

Traditional bollards often sustain significant damage on impact, leading to costly repairs and replacements.

The impact of neglecting street furniture safety

Public safety

High HIC values correlate with a greater likelihood of severe head injuries, which can be life-threatening or result in long-term disabilities.

Financial implications

Frequent repairs and replacements of damaged bollards contribute to increased maintenance costs.

Urban aesthetics

Damaged street furniture can negatively impact the visual appeal of urban areas, affecting community well-being and property values.

The solution

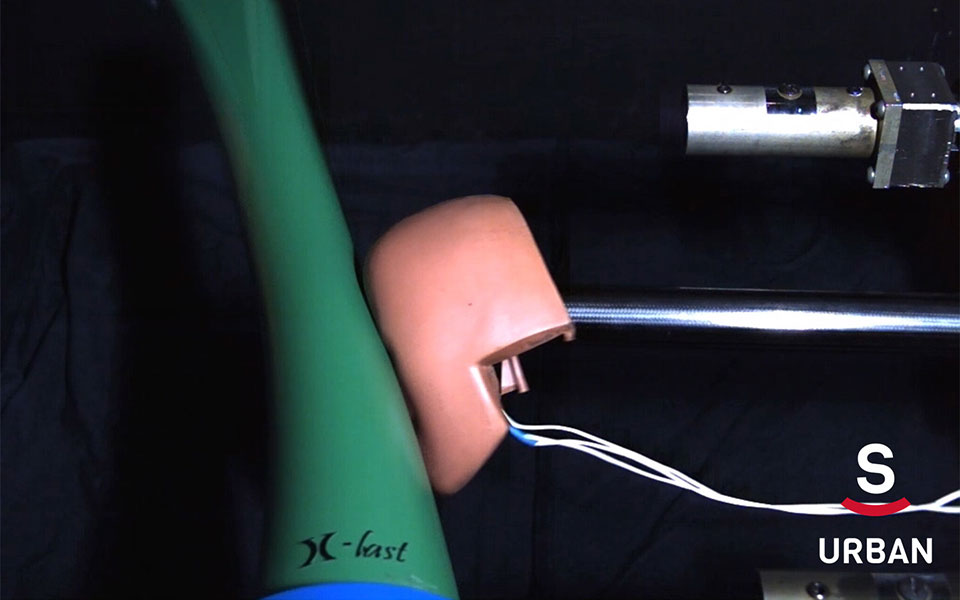

NAL’s X-Last bollard represents a life-protecting choice that enhances safety. The product is:

- Rigid enough to protect pedestrian zones

- Flexible enough to absorb high-impact loads up to 490kg

- Virtually indestructible while remaining maintenance-free

Features include:

- Life-saving low HIC ratings

- Primed for impact absorption

- Self-recovery

- Compliance with safety standards

X-Last bollards have been tested to achieve a HIC value of just 529. This is significantly lower than traditional steel bollards, which have a HIC value of 3,500, exceeding the irreversible injury value of 1000.

Simply put, this saves lives. In fact, it’s safer to collide with the X-Last bollard than the ground.

Constructed from an elastomeric polymer, X-Last bollards can withstand over 1,000 impacts, absorbing and dissipating energy.

(And reducing the force transmitted to individuals, too.)

These bollards can return to their original shape within 30 minutes after a collision – no permanent damage sustained.

In turn, this self-recovery minimises maintenance needs and ensures continuous protection.

X-Last bollards have been independently tested by the automotive engineering and development consultancy company, MIRA.

The results certified the X-Last to EN12767 with a classification of NE4, ensuring they meet stringent passive safety requirements.

Actionable steps for urban planners / contractors

- Assess installation sites

Identify areas with high pedestrian and cyclist traffic where passive safety is a priority - Specify X-Last bollards

Incorporate X-Last bollards into project designs to enhance safety and reduce potential injury severity - Use retention sockets

Install bollards using NAL's retention socket and composite socket systems to facilitate easy replacement and maintenance - Train installation teams

Attend our CPD training to educate installation and maintenance teams on the benefits and proper handling of X-Last bollards to maximise their effectiveness

Implementing your solution

By integrating NAL's X-Last bollards into urban environments, you can:

- Significantly enhance safety measures

- Protect the public while optimising maintenance budgets

- Redesign your streets to make them safer, more practical, and more attractive