Infrastructure problem playbook

Eliminating injury and inefficiency during access cover installation and maintenance

Eliminating injury and inefficiency during access cover installation and maintenance

The problem

Crush risk, back injuries, and herniated discs are just some of the problems associated with installing and maintaining traditional access covers. This isn’t to mention logistical issues and older covers becoming jammed over time.

So, ensuring safe, efficient access to traffic signals and street lighting infrastructure is a persistent challenge for local authorities, contractors and maintenance teams.

The problem

Traditional access covers present known issues such as:

Manual handling challenges

Ductile iron and traditional recessed cover systems require significant effort to lift, increasing the risk of injury.

Security risks

Unauthorised access to critical infrastructure can lead to vandalism, theft, and service disruptions.

Multiple tools requirements

Different access points can often require specialised tools, complicating maintenance processes.

Interference issues

Metal covers can interfere with signals and communications, affecting operational efficiency.

Real-world examples

In 2024, police were called in to investigate a spate of manhole cover thefts in Shropshire and Staffordshire – with over 20 missing covers. Meanwhile, an (unpleasant) online search will avail you of viral videos of what happens when hands get trapped in manhole covers.

The impact of safe access

Enhanced security:

Reducing unauthorised access protects infrastructure and prevents service disruptions.

Improved safety:

Lighter, more ergonomic designs reduce the risk of manual handling injuries.

Operational efficiency:

Standardised tools streamline maintenance and reduce downtime.

Future-proofing:

Non-conductive materials eliminate interference issues, supporting smart city technologies.

The solution

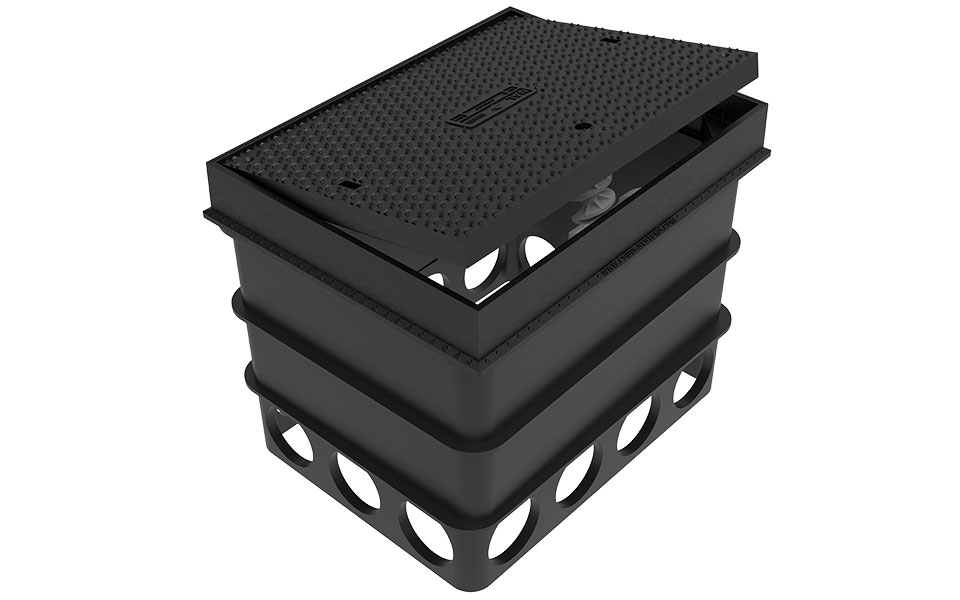

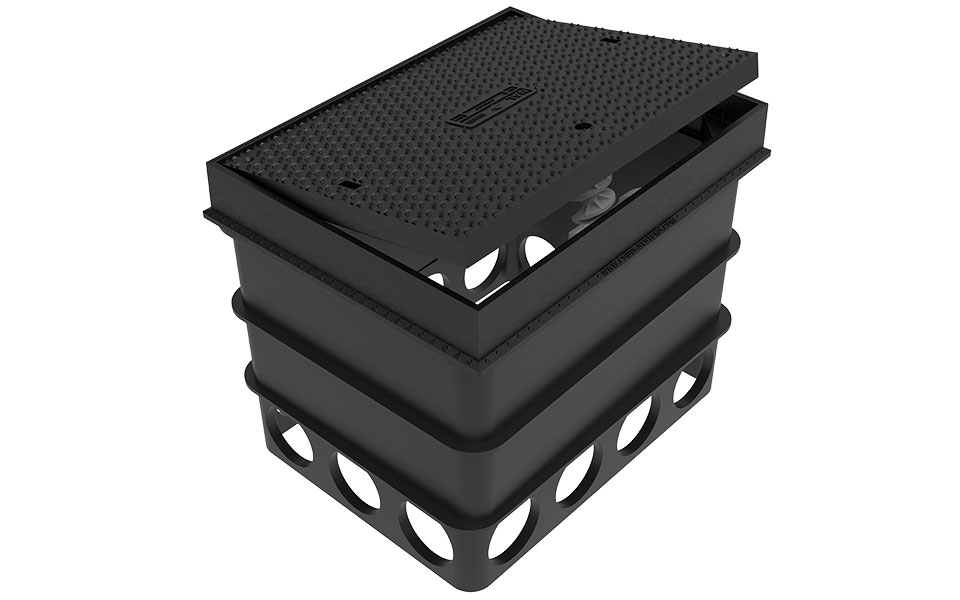

NAL’s LIFTlock® makes access safe, easy, and secure.

We’ve engineered a composite cover and frame system offering a lightweight, lockable cover that can be easily lifted and accessed when required.

Features include:

Locking mechanism:

An integrated worm lock mechanism, ensuring that only authorised personnel with the correct key can access covers.

Automatic locking:

Once the cover is fully lowered into the frame, the mechanism automatically secures it, preventing unauthorised removal.

Safety:

When fully raised, the mechanism holds the cover up, providing a safe area for lifting.

Single-handed operation:

A single operative can safely remove the cover without strain or risk of injury.

Lightweight composite material:

Significantly lighter than ductile iron alternatives, making handling easier and safer.

Stop-point mechanism:

Ensures the cover is partially raised before full removal, allowing for controlled lifting.

Universal tooling:

Uses the same key as NAL retention sockets and cabinet bases, simplifying maintenance workflows.

Non-conductive material:

Eliminates interference with radio signals, supporting smart infrastructure solutions.

Durability:

Resistant to environmental wear, reducing long-term maintenance costs.

C250 load rating:

Suitable for roadside applications, ensuring compliance with industry standards.

Actionable steps for urban planners / contractors

- Assess current access challenges

Identify locations where traditional access covers pose security or handling risks.

- Specify LIFTlock® for new installations

Incorporate LIFTlock® covers into project plans to enhance security and safety.

- Standardise tooling across installations

Where possible, transition to the ‘T’ key system to streamline maintenance operations.

- Train installation and maintenance teams

Attend our CPD training on the proper installation of the LIFTlock® system to ensure optimal performance.

Implementing your solution

By integrating LIFTlock® into access points, you can:

- Reduce manual handling risks and prevent hand injury

- Enhance security and prevent unauthorised access

- Ensure easy, single-operator access

- Simplify maintenance with one key for multiple systems

- Eliminate interference issues