New retention socket head:

Small tweaks, practical gains

NAL retention sockets have become even more efficient. Based on your real-world feedback, we’ve introduced a series of small but practical refinements to our retention socket head design.

After a round of R&D – working both with and for our customers out in the field – we have successfully:

• Enhanced installation efficiency and long-term reliability

• Reduced the number of components required on site

• Provided additional protection against water ingress

Here’s a breakdown of what’s changed in the NAL retention socket head, and why.

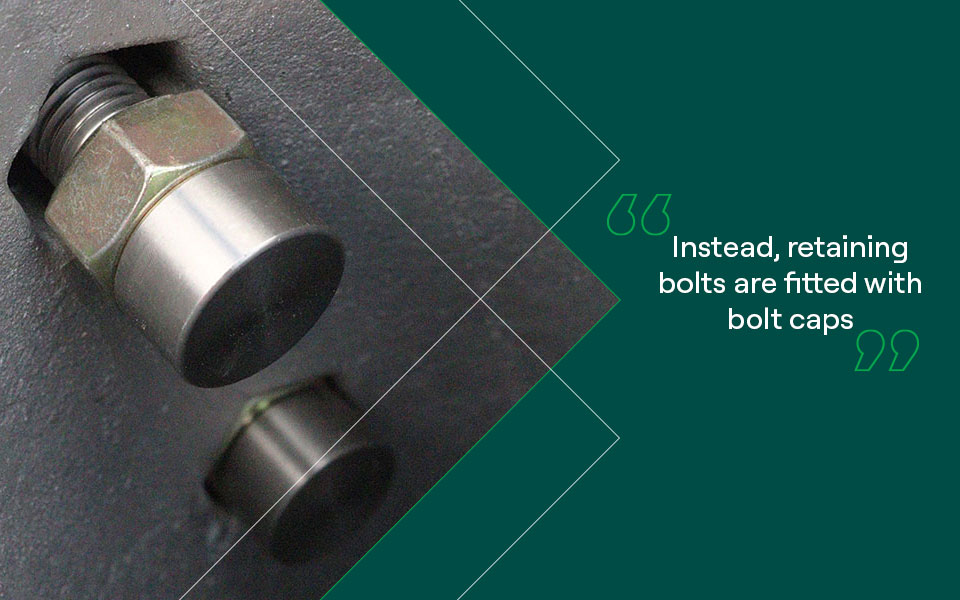

1. Removed pressure plate

Previously, retention sockets included a separate internal pressure plate. This was inserted before installation to ensure the retaining bolts pressed against the plate, not the post itself.

That pressure plate has now been removed. Instead, retaining bolts are fitted with bolt caps, which apply pressure directly and evenly without damaging the inserted column or bollard.

Why it matters:

- Fewer components to manage

- Reduced installation time

- Lower risk of installer error

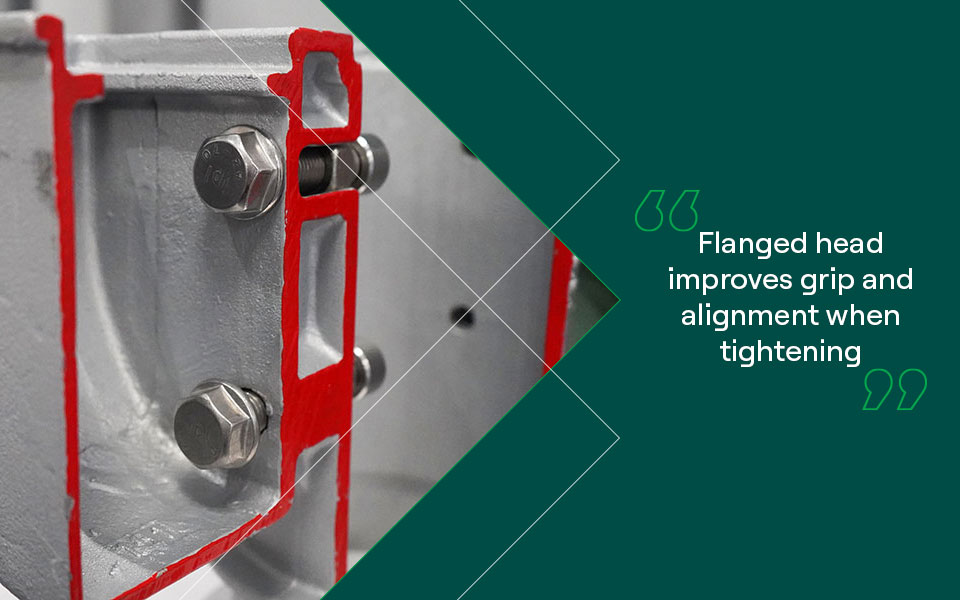

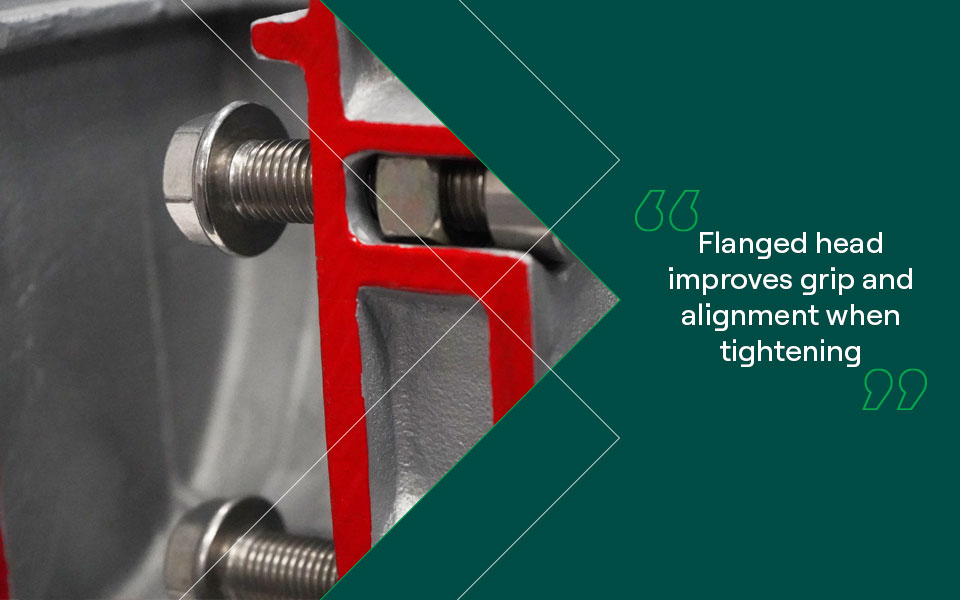

2. Improved bolt design

The retaining bolts have been redesigned with a flanged head, which improves grip and alignment when tightening.

In the previous design, the spanner had to be positioned precisely to avoid slipping over the bolt head. The new flange reduces this risk and speeds up the installation process.

Why it matters:

- Easier, safer tightening

- Less chance of tool slippage

- Improved reliability in all weather conditions

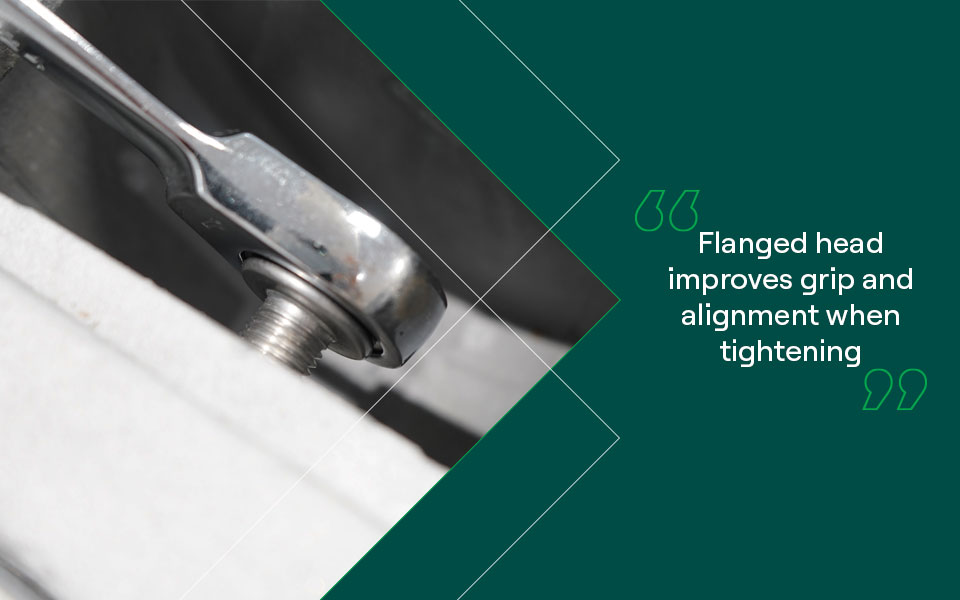

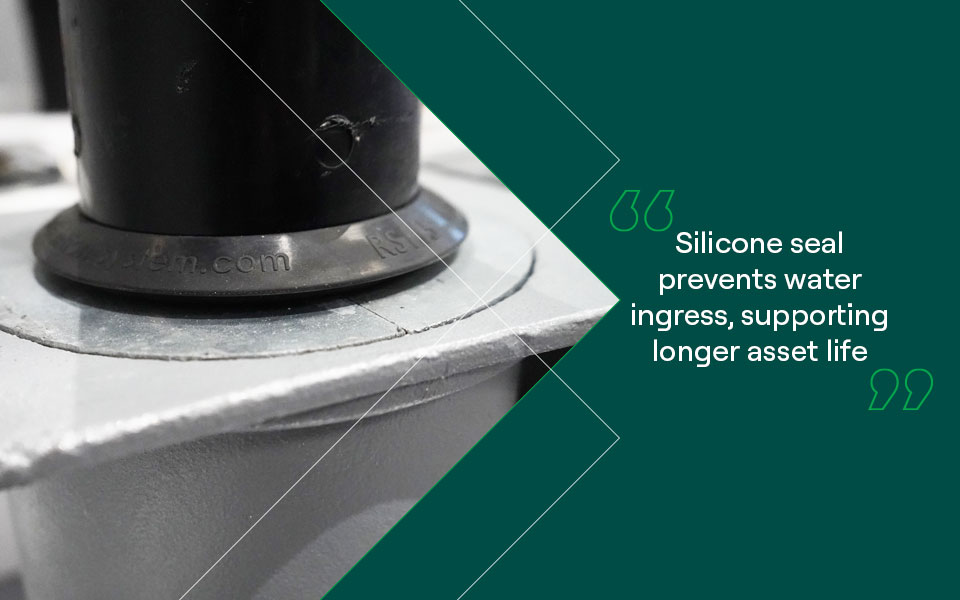

3. New silicone seal included as standard

A pre-fitted silicone seal is now standard on all retention socket heads. This addition helps prevent water ingress into the socket, supporting longer asset life and reducing maintenance requirements.

Why it matters:

- Improved weather protection

- Reduced risk of internal corrosion or water pooling

- No need for installers to apply additional sealing on-site

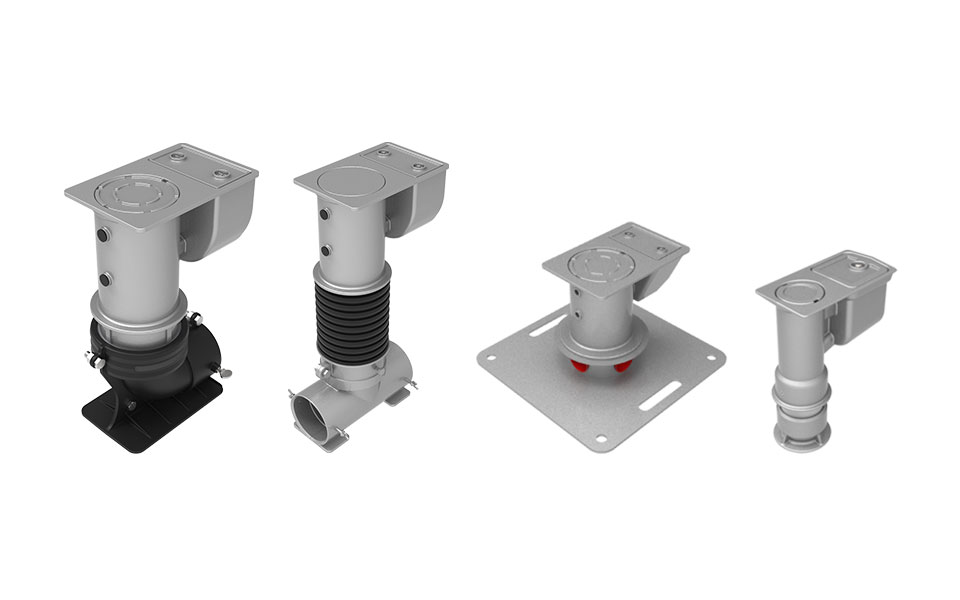

Same compatibility, better usability

These refinements are part of NAL’s ongoing product refinement process. The updated socket heads are consistent across all standard retention socket varieties and remain fully compatible across all standard post types. No changes are required to installation procedures beyond the removal of the pressure plate step.

Installer feedback in action

These changes are the direct result of feedback from installers and contractors across the UK. By addressing small points of friction – such as tool alignment or unnecessary components – we’ve made a widely-used product simpler, faster, and more resilient in the field.

If you’d like more technical detail or want to arrange a demonstration, get in touch with the NAL team.