NAL origin series:

Solving groundworks health and safety challenges with LIFTlock®

Manual handling accounts for more than a third of all workplace injuries. In groundworks, some of the biggest culprits include lifting, lowering, and awkward postures.

Here at NAL, one of the silent hazards most pertinent to our customers was lifting access covers. Local authorities and contractors told us they were contending against crush risk, back injuries, and herniated discs. We thought this could change.

So, we analysed the root causes – weight, repetition, and poor ergonomics – and created a safer way to gain access. Here’s the story behind LIFTlock®: the NAL system designed to solve your groundworks health and safety challenges.

A hidden H&S risk

Traditionally, heavy lifting, awkward movements, and repetitive strain would all be involved to open an access cover. Across traffic signal and highway maintenance, workers frequently encounter access covers that are:

- Unsafe for single-person lifts

- Difficult to prise out with tools

- Warped or seized due to environmental exposure

- Located in congested or uneven ground conditions

- Opened using unsafe tools or poor lifting techniques

These are routine groundworks health and safety hazards that, unfortunately, go under the radar. The result is a culture of “just get it done” that exposes workers to long-term injury risk. (And clients to serious liability.)

Listening to the field: a smarter way in

Our product development process at NAL is simple: listen, observe, and solve.

We spoke to maintenance engineers, highways teams, and local authority clients about the access cover issues they faced daily. Their feedback highlighted central frustrations such as:

- “We need fast access for inspections and service checks – but rushing can lead to trapped fingers.”

- “It’s hard to lift in tight spaces without hurting your back.”

- “It should be a one-person job, but it never is.”

Every story added up to the same conclusion: lifting covers shouldn’t be this hard or this dangerous. So, we reimagined what access could look like.

From input to innovation

The NAL fix was LIFTlock®: a system that turns access cover lifting into a controlled, single‑hand operation.

The LIFTlock® is a composite cover and frame system offering a lightweight, lockable cover that can be easily lifted and accessed when required.

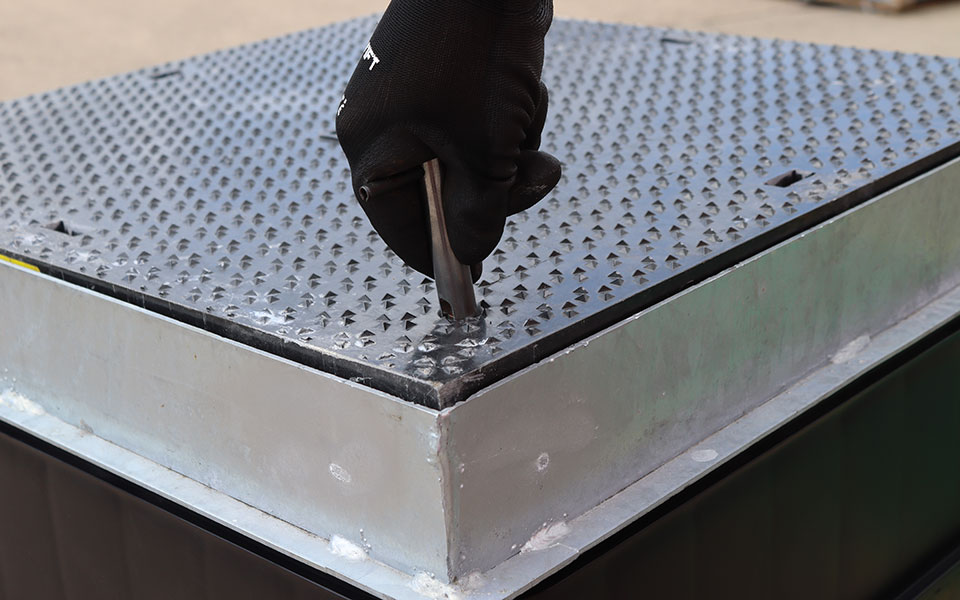

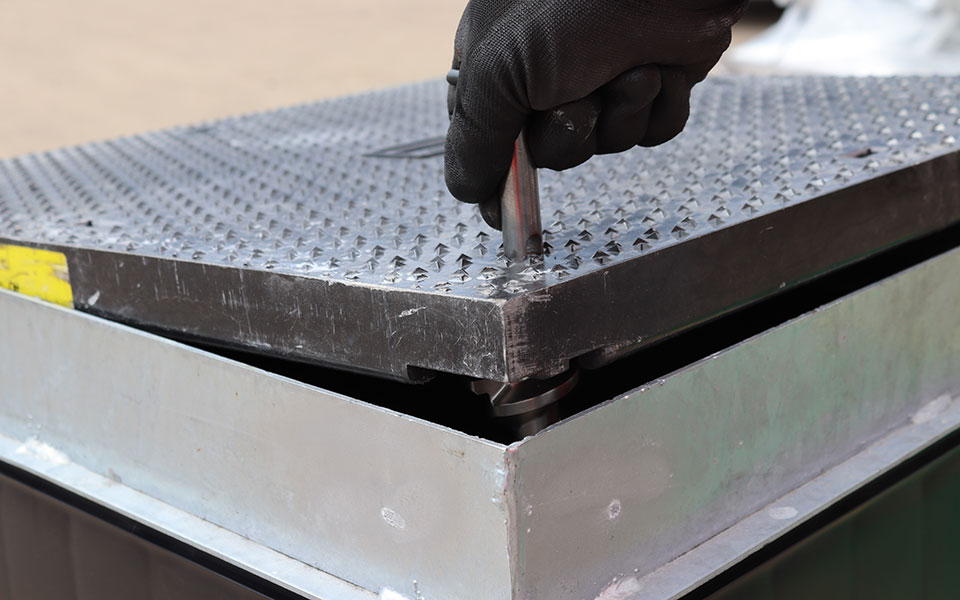

- Uses a unique worm‑and‑screw mechanism fitted into a NAL composite cover, engaging a stop bracket on the opposite side

- Via a simple T-key system, an engineer turns anti‑clockwise to lift the cover

- Allows for a safe, single‑hand lift from the partly raised position

- Rotating clockwise lowers and locks the cover securely again

- Only someone with the correct key can operate the mechanism – locking access and protecting against unauthorised entry

The groundworks health and safety benefits

Our in the field, engineers using LIFTlock® are reporting protected teams, saved time, and reduced hidden risk. By integrating the solution into access points, you benefit from:

- Safe single-person operation

- Elimination of lifting injuries

- Faster access operations

- No specialist tools required

- Added lockable security

- Simplified, standardised maintenance

- Eliminated interference issues

Avoiding the hidden costs of bad ergonomics

The manual handling of access chambers might not make headlines, but its impact is real. Unsafe processes hurt people, productivity, and the bottom line.

- HSE estimates put the cost of manual handling injuries at £1.5 billion annually

- The average musculoskeletal injury results in 20+ days lost per case

- Employers face not just lost time, but compensation claims, fines, and damaged morale

LIFTlock® provides a preventative solution. Our product directly targets the root cause of this overlooked groundworks health and safety risk: required lifting force and awkward handling.

From conversation to transformation

As is typical of NAL products, LIFTlock® was born from the voice of experience. The people closest to the work told us what wasn’t working, and we responded with a new way forward.

If you want to reduce manual handling injuries on your sites, specify LIFTlock® for your next project. We’re always ready to listen and help.